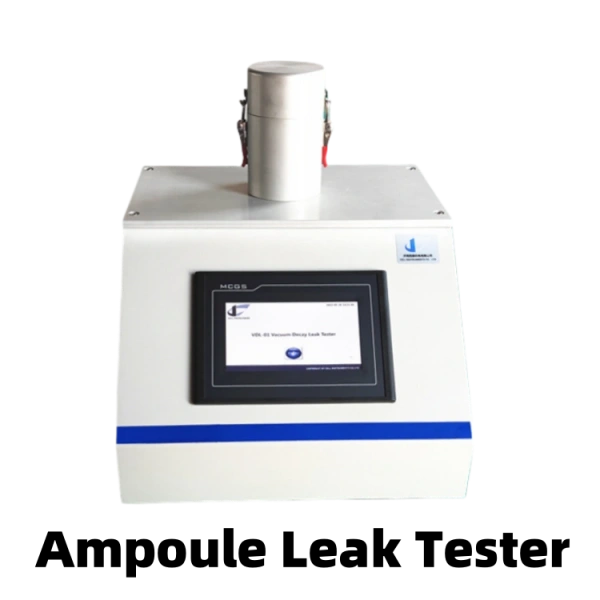

Principle of Vacuum Decay Method:

- Placing the Ampoule into the Sealed Test Chamber

The ampoule is placed inside a sealed testing chamber, which is designed to maintain a vacuum environment. - Evacuating the Test Chamber

A vacuum pump removes the air from the chamber, creating a low-pressure environment. - Pressure Stabilization Stage (Equilibrium Phase)

Once the desired vacuum level is reached, the system maintains a stable pressure for a set period to observe any changes. - Monitoring Pressure Changes

- If the ampoule is properly sealed: The pressure inside the chamber remains stable without significant fluctuations.

- If the ampoule is leaking: Air enters the ampoule through the defect, causing further pressure drop or fluctuations in the chamber, indicating the presence of a leak.